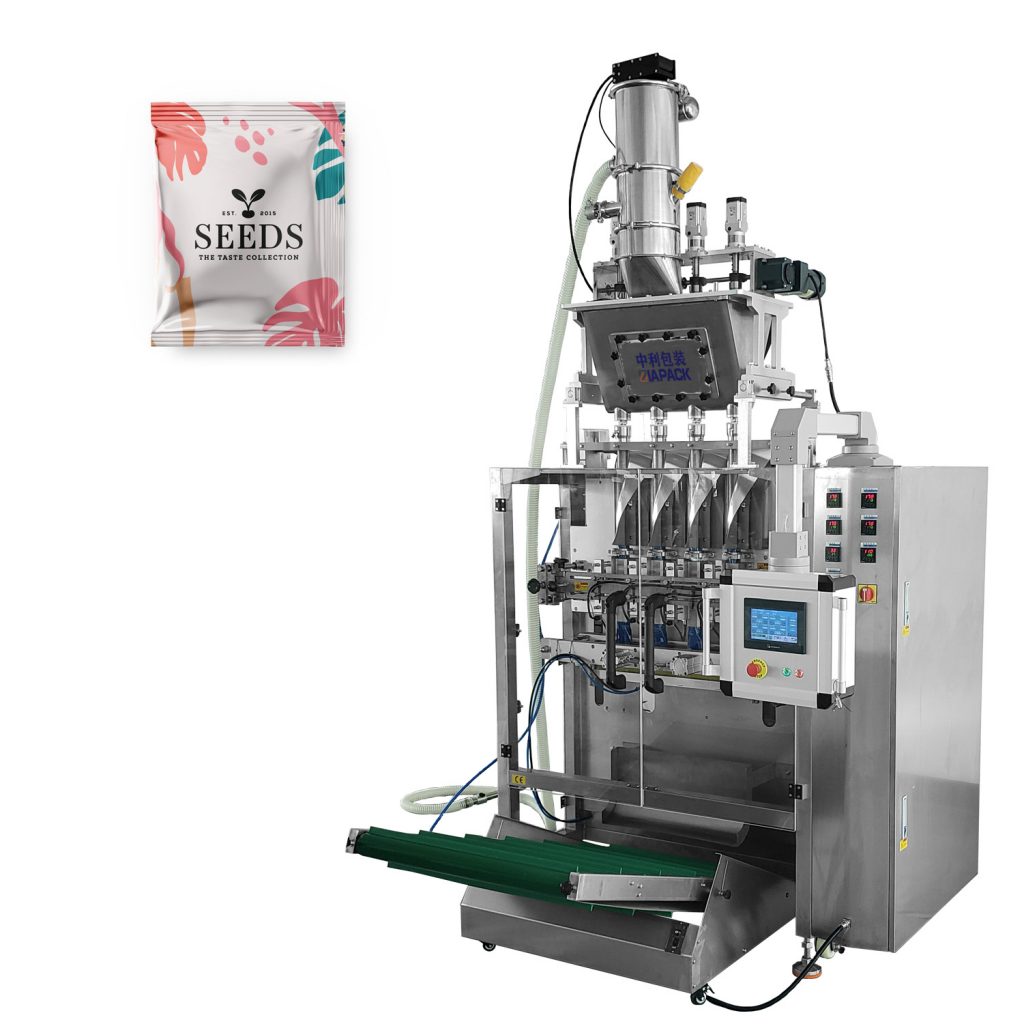

Production :

This machine is special design for packing various product like powder ,sauce ,small granule .The machine can Automatically feeding, measuring volume, making bags, filling, sealing, cutting, printing the lot number and cutting easy tearing notches, finished product conveying. widely use for food & Pharmaceutical industr

Standard Features:

(1).Famous brand PLC control system, large touch screen, convenient to operate;

(2).Film drawing down system by famous bland servo motor control.

(3).Each lane dosing with each famous servo motor;

(4).Advanced design, high precision and fast speed;

(5).Various alarm system to reduce waste;

(6).Photoelectric tracking system for precise bag length and position of film

Specification:

| Model | ZL560-4 |

| Lane number | 4 lanes |

| Packed item | Powder |

| Capacity | About 80--120 bags/min basic on product and film |

| Measuring method | Short auger filling *4 by servo motor |

| Bags size | Length: 50--160 mm Width:70mm |

| Film width | Max.560mm |

| Film thickness | 0.04--0.10mm |

| Sealing type | 3 side sealing sachet |

| Cutting type | Straight cutting with easy tear |

| Printer type | Ribbon stamp printer |

| Film material | Laminated film, like PET/PE, OPP/PE,NY/PE,PET/AL/PE. etc. |

| Air consumption | 0.8Mpa 0.8m3/min |

| Power source | 1N+PE/60HZ/AC220V(380V)/7KW |

| Dimension | L1700x W1300x H2600mm |

| Weight | 600kg |

Application :

Our Services

After-sale service:

We provide you with one year warranty and life long after-sale service, we guarantee the main parts

within 12 months, if the main parts go wrong without human contact within one year, we will freely provide

with you. And after one year, if you need to change parts, we will provide with you with best price and

main it in your site. Whenever and wherever you have technical problems, you can contact us at any time,

we will do our best to support you to solve the problems.

Quality guarantee:

nail polish labeling machine

We are the manufacturer of the machine, as a manufacturer, we guarantee the machine are made of

the best materials, with first-class workmanship, brand new, unused and in all respects with the quality,

specification and performance are stipulated in the contract.

Quality warranty period is within 12 months from B/L date. The manufacturer would repair the

contracted machines free of charge during the quality guarantee period . If the breakdown is due

to the improper use or other reasons, the manufacturer will collect the repair fee.