Applications

Suitable for automatic packaging of liquid,water,milk,juice,sauce,ketchup,chemical liquid,oil etc.

Features

Stainless steel systems

Wide range of package styles include pillow bag, gusseted bag, block bottom bag or quad seal packs

With the ZVF series the production of 3 or 4 side-seal pack is available.

Up to 5 liter filling volume

Pumps for continuous or intermittent liquid feed to bagger

Rugged, durable equipment to withstand severe environment

Customized to meet your production, package style and economic requirements

Optional Device

Filling nitrogen device, gusseted device, punching jaws, chain bags device, PE fillm device,venting device.

Technical Specifications

| Model | ZL-520 |

| Product Size | 1388*1116*536mm |

| G.W | 500kg |

| Speed | 10-30Bags/Minutes |

| Packing material | OPP/CPP OPP/CE PET/PE |

| Electric Voltage | 110V/220V, 50HZ/60HZ |

| Bag Width | 260mm |

| Max width of the Film | 360mm |

| Material | 201/304 Stainless Steel |

| Brand | IAPACK/OEM |

| Power | 3KW |

| Warranty | 1 year |

| Packing Size | 1398*1126*546mm |

| MOQ | One Set |

| Payment | T/T, L/C, CASH, D/P, VISA |

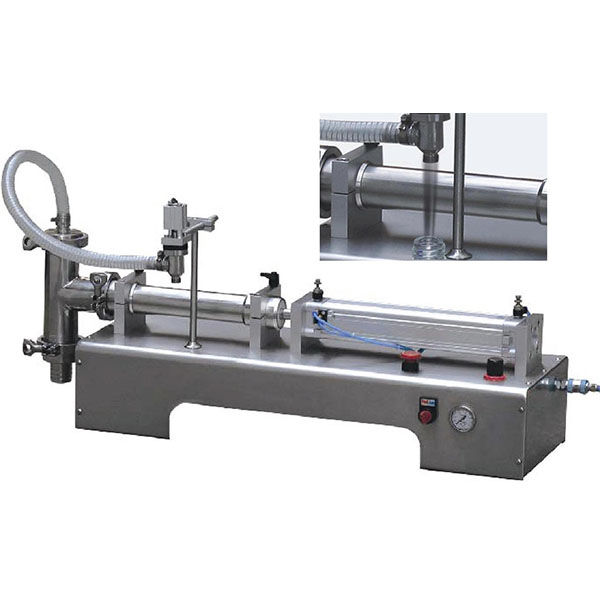

Single Head Piston Filler For Viscous Liquid

Horizontal single head piston filler for viscous liquid,such as ketchup, mayonnaise, cream, butter, jam, honey, shampoo etc.

Principal Features:

Standard with Airtac Piston.

All piston filler made from S/S 304 grade stainless steel and aluminum conforms to GMP.

Viscous Liquid Model with stainless steel product hopper

Operated by foot pedal switcher or by automatic timer.

With Anti-leaking system

Product suction and dispensing speed adjustable.

No-Tools for set-up and adjustment.

Sanitary tri-clamp connections easy wash

Quick release nozzle and feed pipe

Small footprint for simple bench mounting

Be able to be equipped with other automatic packaging machine

Most commonly applicable for pharmaceutics, daily chemicals, foodstuffs, cosmetics, pesticides and other industries.

Option:

Festo Piston

Food and pharmaceutical S/S 316 grade stainless steel contact parts.

For some viscous liquid, the mixing & heating hopper is option.

Standard with electric solenoid control, we have pneumatic solenoid valve to work without electric option at full Pneumatic Driven

Technical Specifications:

Air Consumption: 0.6CBM/H

Air Supply Pressure: 0.4-0.6Mpa

Operation Efficiency: 10-20 bottles per min (depends on product and container size)

Filling Precision: ≦±1%

Dimension & Weight: Variable, depending on the application