ZL8-230 Rotary bag taking filling sealing machine for doypacker

Function and characteristics

- Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

- Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production.

- Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

- Safety device: Machine stop at abnormal air pressure, heater disconnection alarm。

- The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time.

- It match with the glass safety door. that it could protect the safety of operators. At the same time, it could prevent dust.

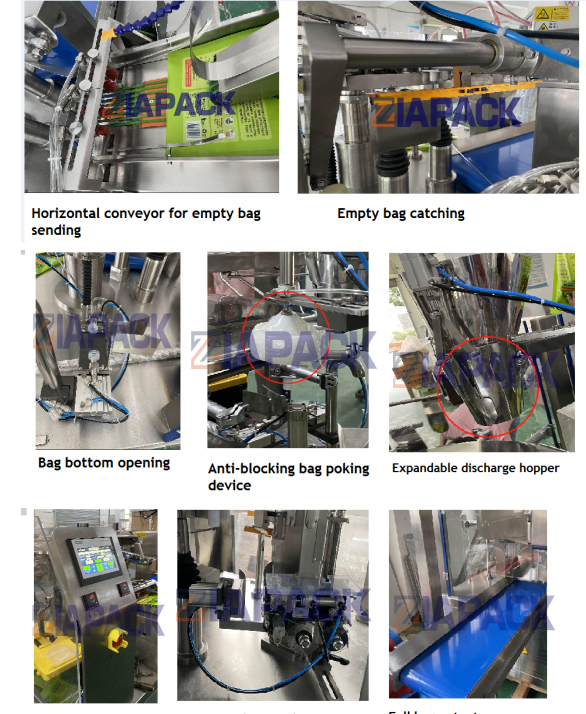

- .Horizontal conveyor style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

- Use the plastic bearing, don’t need put on oil, less pollution.

- Use no oil vacuum pump, avoid polluting the environment in the production.

- The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

- Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

- With different feeders changed to pack solid, liquid, thick liquid ,powder and so on.

Technical parameters

| Model | ZL8-230 |

| Working position | Eight-working position |

| Pouch material | Laminated film/PE film |

| Pouch pattern | Doy packer with zipper |

| Pouch size | W:140-210mm L:150-300mm |

| Speed | 20-50pouches/min(The speed depends on the product status and filling ) |

| Weight | 1400KGS |

| Voltage | 380V 3phase 50HZ |

| Total power | 4KW |

| Compress air | 0.6m3/min(supply by buyer) |